Automation plays a crucial role in modern advanced technology. People apply it in homes and industries. Self-checkout scanners at grocery stores scan and total items in seconds. Smart thermostats adjust room temperature before residents wake. Chatbots handle customer queries without human help. Robots assemble car bodies with precise movements. It reduces manual work and ensures consistent performance. It frees people to focus on creative and strategic tasks. This article offers a clear overview of the topic. It defines the concept. It traces its history. It explains various types. It describes how the technology works. It lists key advantages and drawbacks. It examines real-world applications. It provides resource links.

What is Automation?

The term refers to the use of machines or software to perform tasks that people once did manually. Professionals also call it mechanization, automatic control, or robotics. The approach includes simple actions like sending reminders and complex operations such as welding car parts with industrial robots. It relies on predefined rules or adaptive algorithms. Devices then execute tasks with speed and consistency. For example, a thermostat learns heating preferences and then adjusts the temperature without human input. This solution improves accuracy and frees staff to focus on strategic work. The concept applies across countless modern systems.

Breaking Down Automation

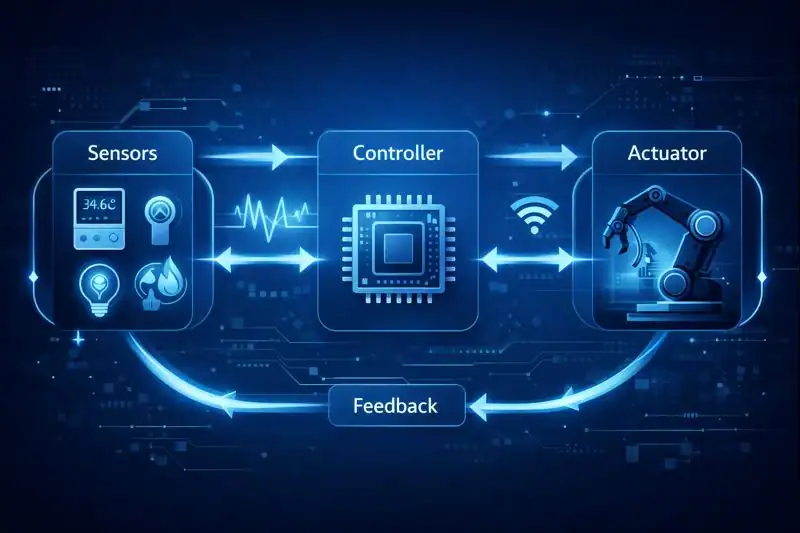

Automation has four main parts. First, sensors collect data. Second, controllers interpret the information. Third, actuators perform the required actions. Fourth, feedback loops confirm the results. For example, a smart irrigation setup uses moisture sensors to read soil conditions. A controller then sends commands to valves. The valves open to water the plants. The setup then checks the moisture level again. This cycle of sensing, deciding, acting, and checking runs continuously. The technology combines hardware and software. It relies on years of innovation. These components work together to handle repetitive duties. They save time and reduce errors.

History of Automation

The journey began during the Industrial Revolution. Water wheels and steam engines powered textile mills. In 1913 Henry Ford introduced the moving assembly line. It increased production speed. In the 1950s engineers developed programmable logic controllers. Manufacturers then used computers to oversee machines. In the 2000s companies adopted software-based solutions and robotic process automation. They used cloud tools to automate digital tasks.

| Year | Milestone | Description |

|---|---|---|

| 1760s | Early mechanization | Water wheels and steam engines powered textile machines. |

| 1913 | Assembly line introduction | Henry Ford introduced the moving assembly line in car production. |

| 1950s | Programmable controllers | Engineers deployed programmable logic controllers in factories. |

| 2000s | Software-based solutions | Companies adopted RPA and cloud tools to automate digital tasks. |

Types of Automation

Fixed Automation

This method serves one specific task with little change. Manufacturers design these systems for high volume. For example, a stamping press cuts metal parts in the same way thousands of times. Engineers set up the machine before each run. It then operates without stopping or altering. This approach works well when companies require large quantities. It also ensures consistent cycle times and low error rates.

Programmable Automation

This option allows machines to handle different tasks through new programs. Companies use it for batch production. CNC machines show a clear example. One week they sculpt engine parts from metal. The next week they carve decorative items. Engineers upload fresh code for each job. This method takes more time to set up than fixed systems. It fits well when businesses need varied product runs. It lets teams adjust settings to balance cost, quality, and speed.

Flexible Automation

This solution reduces the time and effort required to switch tasks. Workers can reconfigure systems in minutes or hours. They use modular cells, robots, and smart tools. For example, warehouse robots can pick items of different shapes and sizes. Vision systems guide each movement. Software adjusts robotic motions in real time. This model supports on-demand production. It maximizes equipment use. Companies apply it in dynamic settings such as e-commerce fulfillment centers. It demands a large upfront investment. However, it delivers rapid responsiveness and minimal downtime.

How Does Automation Work?

The process follows four steps in a cycle. First, sensors or input devices gather data. The information can include temperature readings, user clicks, or stock levels. Second, software or controllers analyze this input based on preset rules or algorithms. Third, actuators or code modules carry out the actions. They might open a valve, send an email, or update a database. Fourth, feedback devices verify the results. They send new data back to the system. Engineers can then adjust rules or settings. The cycle repeats continuously. These systems can loop thousands of times per minute. They maintain precision and speed. Integration with databases, APIs, and user interfaces ensures smooth operation.

Pros and Cons

This approach offers clear benefits and some drawbacks. Companies must evaluate these factors before investing. The table below lists the main advantages and disadvantages.

| Pros | Cons |

|---|---|

| It improves output. | It requires high capital. |

| It reduces errors. | It may displace workers. |

| It lowers long-term cost. | It can be complex to deploy. |

Uses of Automation

This technology can transform many industries. It enhances quality, speed, and consistency. The examples below show how companies apply it in real situations.

Manufacturing

Industry first adopted this solution in manufacturing. Robots weld car frames with high precision. CNC machines carve engine parts from metal. Automated conveyor belts transport pieces between workstations. Sensors monitor production in real time. The system can detect errors and halt the line. Workers then fix issues. This method reduces defects and waste. It keeps factories running day and night.

IT and Software

IT firms rely on this process for testing and deployment. Developers write scripts to run tests and compile code. Continuous integration tools then push changes to test servers. The system checks for errors at each step. If the build passes, it moves to production. Automated monitoring tools track server health. They trigger alerts or add capacity as needed. This strategy keeps websites stable and secure. It allows engineers to focus on new features.

Healthcare

Healthcare providers use these methods to improve patient care. Hospitals install automated dispensing machines for medications. The systems record each dose and verify the correct drug. Laboratories deploy robots to handle blood tests. These robots process thousands of samples with precise timing. Remote monitoring devices send patient data to doctors. The system alerts staff if vital signs change. Chatbots manage routine questions and schedule appointments. This approach frees medical professionals to offer more direct patient care.

Resources

- GeeksforGeeks. What is Automation?

- Spiceworks. What Is Automation and Why It Matters

- IBM. Automation – The Future of Business Processes

- Techopedia. Automation Definition

- Britannica. Automation