Overview

The chip shortage has been a defining issue for industries across the globe, from automotive manufacturing to consumer electronics. This shortage, which started in 2020, is still causing major disruptions in October 2024, impacting the supply chain, product development, and technological advancements. While the situation has evolved, demand for chips continues to outstrip supply, particularly with the surge in artificial intelligence (AI) and digital transformation. In this article, we’ll explore the current state of the chip shortage, its relevance to industries, and the latest developments in this ever-pressing issue.

The Importance and Relevance of the Chip Shortage

Chips, or semiconductors, power almost every device we use today. Whether it’s your smartphone, computer, car, or even household appliances, chips are at the heart of modern digital technology. With increasing demand for digital products, and the integration of AI into more industries, the global demand for chips has skyrocketed.

In 2024, this shortage remains critical for businesses, consumers, and governments. From delays in new car production to constrained supplies of computer parts, the chip shortage continues to influence how companies plan and manage their operations. Jabil recently reported that industries reliant on digital technologies are feeling the most significant impact, particularly in automotive, consumer electronics, and AI-driven sectors.

Recent Breakthroughs

Despite the challenges, there have been some breakthroughs in managing the chip shortage. Key industry players are investing in advanced chip production facilities. For example, companies like TSMC and Intel have announced multi-billion dollar investments in new fabrication plants, or “fabs,” designed to boost production capacity. Additionally, the U.S. and Europe have made strategic moves to increase domestic semiconductor manufacturing, aiming to reduce their dependence on global supply chains. As noted by Forbes, these efforts have started to mitigate some pressure on the market, but full recovery is still a few years away.

AI’s explosive growth is one of the primary factors contributing to the ongoing demand for chips. In a recent report from CNBC, it was noted that AI technologies, which require highly specialized semiconductors, have seen a 35% increase in demand. These AI chips are more complex and harder to manufacture, exacerbating the shortage.

Emerging Applications

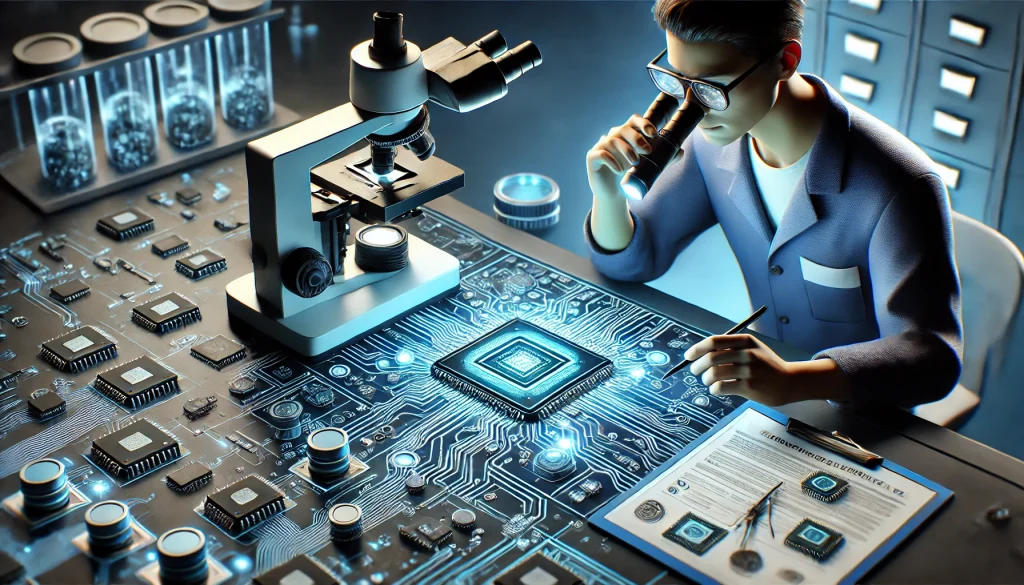

AI and digital transformation have become key drivers for semiconductor demand in 2024. The rise of AI-driven technologies, from autonomous vehicles to smart home devices, requires advanced chips that can handle complex computational tasks. AI systems like machine learning algorithms and neural networks rely on GPUs (Graphics Processing Units) and specialized AI chips that allow them to function efficiently.

One emerging application of AI chips is in healthcare. Advanced AI-powered diagnostic tools require high-speed, reliable semiconductors to process vast amounts of data. As AI integrates deeper into healthcare and other fields, the demand for semiconductors designed to handle these tasks will only continue to rise.

The role of chips in digital infrastructure is also increasing. Data centers, which support cloud services and the digital economy, rely on massive amounts of computing power. These centers are critical for supporting AI models and the growing demand for streaming and online services. Without enough chips, the development of this infrastructure is delayed, and companies struggle to meet global digital demand.

Integration with Other Technologies

The semiconductor shortage has not only impacted industries that use chips directly but has also slowed down innovation in other areas of technology. For example, the development of electric vehicles (EVs), which require a higher number of semiconductors than traditional vehicles, has slowed due to chip scarcity. Bain & Company highlighted that the EV market is facing delays in production as car manufacturers grapple with chip shortages. This has resulted in longer waiting times for consumers and delayed launches of new vehicle models.

Chips are also integral to the 5G network expansion. With telecommunications companies racing to implement 5G infrastructure, the shortage is posing significant delays. 5G technology relies on high-performance chips to manage the massive data transfer speeds and connectivity improvements it promises. The delays in chip manufacturing have, in turn, slowed down the global rollout of 5G, which is essential for supporting the next generation of digital connectivity.

User Experience Improvements

While the shortage has posed challenges, it has also driven innovation in chip design and production. Manufacturers are investing in more efficient chips that use less power and provide better performance. This focus on efficiency is improving user experiences, particularly in devices like smartphones and laptops, where battery life and processing power are critical factors.

For example, consumers have noticed improvements in battery life on their mobile devices and faster processing speeds in computers and gaming consoles. These improvements are the result of manufacturers focusing on producing higher quality, efficient chips in smaller quantities. Despite fewer products on the market, those that do reach consumers are often of higher quality, providing better overall experiences.

Challenges in Addressing the Chip Shortage

Despite the progress, the chip shortage is far from over. In fact, October 2024 continues to show that demand for chips exceeds supply, especially with the rise of AI. JPMorgan has pointed out that supply chain constraints and geopolitical tensions, particularly between the U.S. and China, are making it difficult to meet global chip demand. Governments and industry leaders are trying to balance national security concerns with the need to keep the global supply chain open.

One major challenge is the complexity of semiconductor manufacturing. Building a chip is a delicate process that can take months to complete. Additionally, the factories, or fabs, that produce these chips require significant investments, advanced technology, and highly skilled workers. Any disruption in the supply of raw materials, such as silicon, or geopolitical issues that delay transportation, can cause further bottlenecks.

At the same time, climate-related disasters, such as droughts in Taiwan (a major chip production hub), have further complicated manufacturing efforts. The shortage of water has directly impacted the ability of fabs to operate at full capacity, leading to reduced output at a time when the demand is higher than ever.

Conclusion

The chip shortage continues to be a significant issue globally, with wide-reaching effects on industries, consumers, and technological advancement. While efforts are being made to increase semiconductor production capacity, demand is expected to outpace supply for the foreseeable future, particularly with the rise of AI and other digital technologies. However, there is hope on the horizon as new fabs come online, and companies innovate to produce more efficient and powerful chips.

It’s essential for businesses and consumers alike to remain aware of the developments in the chip shortage, as it will continue to influence the availability of everything from computers to electric vehicles. As we move through 2024, staying informed and proactive in adapting to these shortages will be crucial for success in this increasingly digital world.

FAQ

What caused the global chip shortage?

The global chip shortage was caused by a combination of factors, including pandemic-related disruptions, increased demand for electronics, and supply chain constraints.

How long will the chip shortage last?

Experts predict that the chip shortage will persist into 2025 due to rising demand for semiconductors in AI, automotive, and consumer electronics industries.

How is the chip shortage affecting consumers?

Consumers are facing longer wait times for products like cars, smartphones, and computers, and may also see price increases due to limited supply.