If you’ve ever picked up a part and thought, “How is this so light but feels unbreakable?”, you’ve met the magic of Carbon Fiber Reinforced Polymer. In today’s materials science Innovation, Carbon Fiber Reinforced Polymer is getting a second wind thanks to smarter manufacturing, tougher nano-enhancements, and serious progress on recycling. The result: Carbon Fiber Reinforced Polymer is moving beyond “premium aerospace material” into a practical option for EVs, infrastructure, wind energy, and next-gen consumer products. Let’s break down what’s changed and why it matters.

What Happened

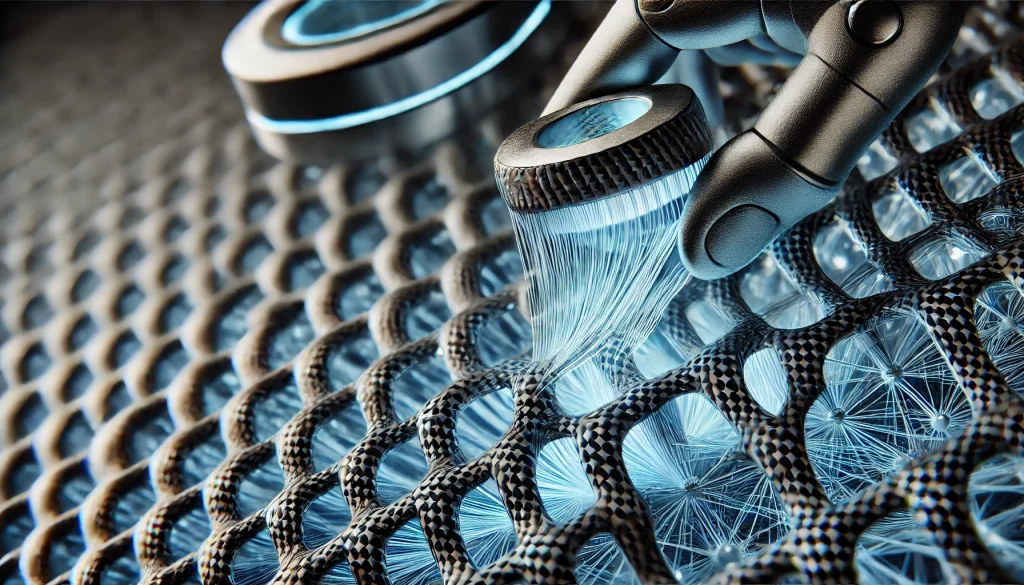

The big story is momentum across the whole Carbon Fiber Reinforced Polymer ecosystem: how it’s made, how it performs, and what happens at end-of-life. On manufacturing, automated processes like Automated Fiber Placement (AFP) and improved winding methods are pushing more precision and better material efficiency—key steps toward lowering costs and scaling Carbon Fiber Reinforced Polymer for broader industries.

On performance, nano-reinforcement is a major leap. Recent reviews and studies highlight how nanoparticles (including carbon nanotubes and graphene-related fillers) can improve toughness, fatigue performance, and damage resistance—addressing one of the classic concerns around CFRP in impact-heavy environments.

And on sustainability, chemical recycling (solvolysis) is increasingly treated as a front-runner for recovering higher-quality fibers from thermoset composite waste—crucial for making CFRP more circular.

When and Where

Your draft frames these breakthroughs around October 2024—and that timing lines up well with late-2024 research activity in smart and nano-enhanced composites (including publications accepted and released around September 2024).

What’s changed since then is the confidence and volume of work: automated manufacturing research continues to expand through 2024, and composite recycling efforts have moved toward faster, less fiber-damaging processes in 2025-focused industry updates.

Who is Involved

Multiple groups are shaping the next chapter of Carbon Fiber Reinforced Polymer, and it’s not just one “hero company”—it’s an ecosystem.

Researchers and universities are leading much of the materials progress, especially in nano-reinforcement (improving toughness, fatigue resistance, and conductivity) and in smart composites for sensing and structural health monitoring. These teams publish the core evidence that helps industry trust new formulations of Carbon Fiber Reinforced Polymer.

Industrial manufacturers and automation specialists are heavily involved on the production side, pushing automated fiber placement (AFP), filament winding, and faster inspection methods so Carbon Fiber Reinforced Polymer parts can be made at scale with less waste. This includes equipment makers, aerospace-grade composite fabricators, and automotive suppliers trying to make cycle times and costs workable for higher-volume production.

Recycling and circular-economy organizations are increasingly central. Groups working on solvolysis and other chemical/thermal recycling routes are trying to recover higher-value fibers and reduce landfill disposal of composite waste—one of the biggest barriers to broader Carbon Fiber Reinforced Polymer adoption. Their work helps turn CFRP from “hard to recycle” into “worth recovering,” which matters for regulations and corporate sustainability targets.

End-user industries—aerospace, automotive/EV, wind energy, rail, construction, and even biomedical—also play a direct role by funding pilots, defining performance requirements, and stress-testing Carbon Fiber Reinforced Polymer in real environments. For example, construction and infrastructure players drive demand for corrosion-resistant reinforcement systems, while EV and mobility teams push for lightweighting and integrated sensing.

Why It Matters

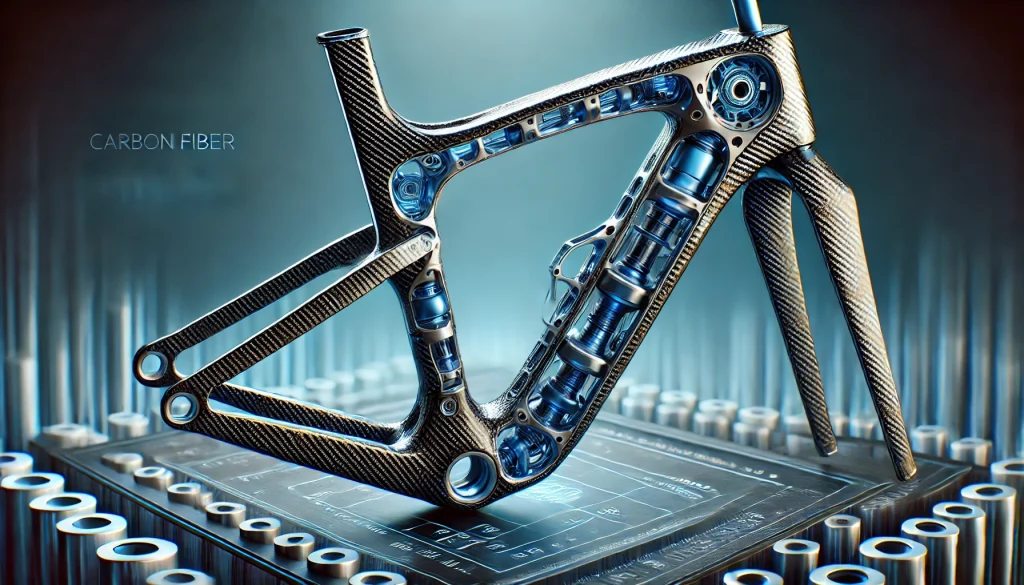

This matters because Carbon Fiber Reinforced Polymer is one of the few materials that reliably delivers “lighter + stronger” at the same time—exactly what transportation, energy, and infrastructure need right now. For EVs, every kilogram saved can translate into better range or smaller battery requirements. For aircraft, less weight can mean lower fuel burn. For wind turbines and industrial structures, durability and corrosion resistance extend service life.

What’s especially exciting is how CFRP is becoming more “multifunctional.” Newer research highlights self-sensing behavior (piezoresistive response) and even potential roles in energy harvesting or storage—think structural parts that can also monitor themselves or contribute to power systems.

Pair that with embedded sensing and monitoring and you get CFRP that supports predictive maintenance—less downtime, fewer catastrophic failures, and safer systems. That’s futuristic technology made practical, especially when paired with iot devices for real-time structural health data.

On the business side, expanding Carbon Fiber Reinforced Polymer adoption can also stabilize supply chains by reducing reliance on heavier metals in certain applications, while enabling faster redesign cycles when products must meet new standards. In consumer markets, Carbon Fiber Reinforced Polymer helps brands deliver premium performance—stiffer bikes, stronger laptops, lighter sports gear—with fewer compromises. And for sustainability, better recycling and reuse pathways mean Carbon Fiber Reinforced Polymer can shift from a “performance-only” choice to a smarter lifecycle choice, especially as regulations and procurement teams increasingly evaluate total environmental impact alongside strength and cost.

Quotes or Statements

One of the clearest signals that recycling is becoming central to CRFP strategy is how solvolysis is framed: it’s often described as promising because it can recover “nearly undamaged fibers for reuse,” which is a big deal given carbon fiber’s high production footprint.

Industry-facing explainers also emphasize that cost reduction and cycle-time improvements are key to making Carbon Fiber Reinforced Polymer viable for mass production contexts like automotive.

Conclusion

As of October 2024, Carbon Fiber Reinforced Polymer (CFRP) remains at the forefront of material innovation. Its lightweight strength, corrosion resistance, and adaptability make it essential across many industries. Recent manufacturing breakthroughs and smart technology integration drive wider adoption, while challenges like cost and recyclability are being addressed.

For both businesses and consumers, CFRP’s benefits in transportation, construction, and everyday products highlight its potential to shape future technology. Staying updated on CFRP advancements will be crucial for leveraging its full potential.

FAQs

What is Carbon Fiber Reinforced Polymer used for?

CFRP is used in industries like aerospace, automotive, and construction for its strength-to-weight ratio, durability, and corrosion resistance.

What are the challenges of using CFRP?

Challenges include the high cost of production, limited recycling methods, and the brittleness of the material in certain applications.

How is CFRP improving user experiences?

CFRP enhances user experience by providing lighter, stronger, and more durable products, such as electric vehicles, aircraft, and high-end sports equipment.

Resources

- ResearchGate. Applications and Future Trends of Carbon Fiber Reinforced Polymer Composites: A Review.

- CRP Technology. Carbon Fiber Reinforced Polymer (CFRP) Guide.

- Advances in Engineering. Advancements in Carbon Fiber Reinforced Polymer Matrix Composites: History, Applications, and Future Innovations.

- Fibrwrap Construction. What is Carbon Fibre Reinforced Polymer (CFRP)? A Guide to Structural Strengthening and Repairs.

- MDPI. Carbon Fiber Reinforced Polymer (CFRP) in Building Applications.