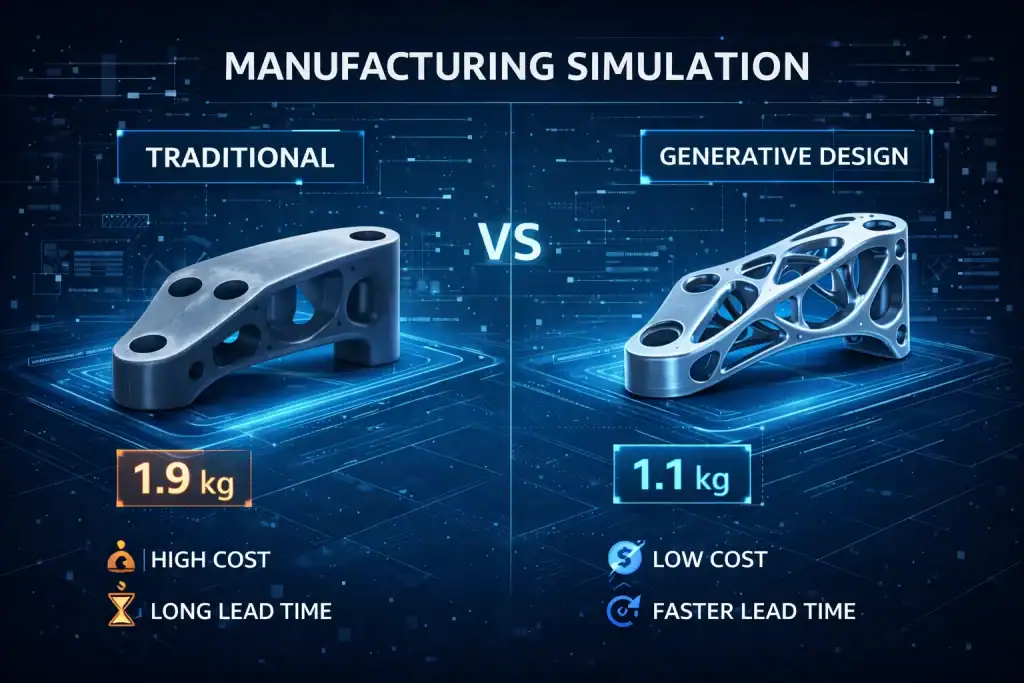

Generative design is a transformative approach to innovation in fields like architecture, engineering, and product design. Powered by algorithms and AI, it revolutionizes how we create, offering solutions that are efficient, sustainable, and creative. Understanding it is crucial as industries evolve towards more adaptive, data-driven methods of problem-solving. In manufacturing specifically, Generative Design helps teams balance strength, weight, cost, and manufacturability—often revealing shapes humans wouldn’t typically sketch, but machines can confidently produce. As additive manufacturing and advanced CNC processes grow, Generative Design becomes even more practical because complex geometries are easier to build than ever before.

What is Generative Design?

Generative design is a design methodology that uses algorithms and artificial intelligence to generate a wide array of potential solutions to a given problem. Unlike traditional design methods, which rely heavily on human intuition and experience, it leverages computational models to explore vast possibilities within specific constraints. This approach is particularly relevant in industries where optimization and efficiency are paramount, such as manufacturing, architecture, and even fashion.

At its core, it involves inputting parameters like materials, costs, and performance criteria. The system then iterates through thousands or even millions of design possibilities, presenting options that best meet the outlined objectives. This methodology is often synonymous with AI-driven creativity or algorithmic design within professional circles. A major benefit is that Generative Design can explore trade-offs quickly—like choosing between slightly higher material use for easier machining, or lower weight for better performance. This makes decision-making faster because teams can compare multiple “best-fit” options instead of debating a single design direction.

Breaking down Generative Design

It blends creativity with computational power. While it is inherently tied to modern AI advancements, its foundation lies in decades of computational geometry and engineering research.

Key Components of Generative Design

- Input Parameters: Designers specify goals, such as weight reduction, strength, or aesthetics.

- Algorithms and AI Models: Sophisticated algorithms simulate and evaluate countless iterations based on the parameters provided.

- Output and Analysis: The system outputs optimal solutions, which can then be refined or manufactured.

For example, in automotive engineering, generative design helps create lighter, more durable vehicle components by evaluating materials, structural strength, and aerodynamics simultaneously. This approach reduces material waste and speeds up production.

Origins and History

It as we know it emerged from a confluence of computational advancements and the need for adaptive design solutions. While the term gained prominence in the 21st century, its roots can be traced back to early CAD (computer-aided design) technologies in the 1960s.

| Era | Milestone | Impact |

|---|---|---|

| 1960s | Introduction of CAD systems | Laid the groundwork for computational design. |

| 1990s | Rise of parametric modeling | Enabled more adaptive, data-driven workflows. |

| Early 2000s | Adoption of generative algorithms in architecture | Fostered complex, efficient design structures. |

| Present Day | AI and machine learning integration | Revolutionized industries with real-time adaptability. |

For instance, the innovative use of generative design in the creation of the Airbus A320’s partition panel demonstrates how it has matured from theoretical to practical applications.

Types of Generative Design

It spans multiple domains, each tailored to specific industries. Here’s an overview of its variations:

| Type | Description |

|---|---|

| Topology Optimization | Focuses on reducing material use while maintaining structural integrity. |

| Parametric Design | Uses adjustable parameters to produce diverse variations of designs. |

| AI-Driven Generative Design | Employs machine learning to predict and refine outcomes. |

| Evolutionary Design | Mimics natural selection to evolve the best solutions. |

For instance, architects may use parametric design to create stunning, adaptive building facades, while engineers might apply topology optimization to streamline component manufacturing.

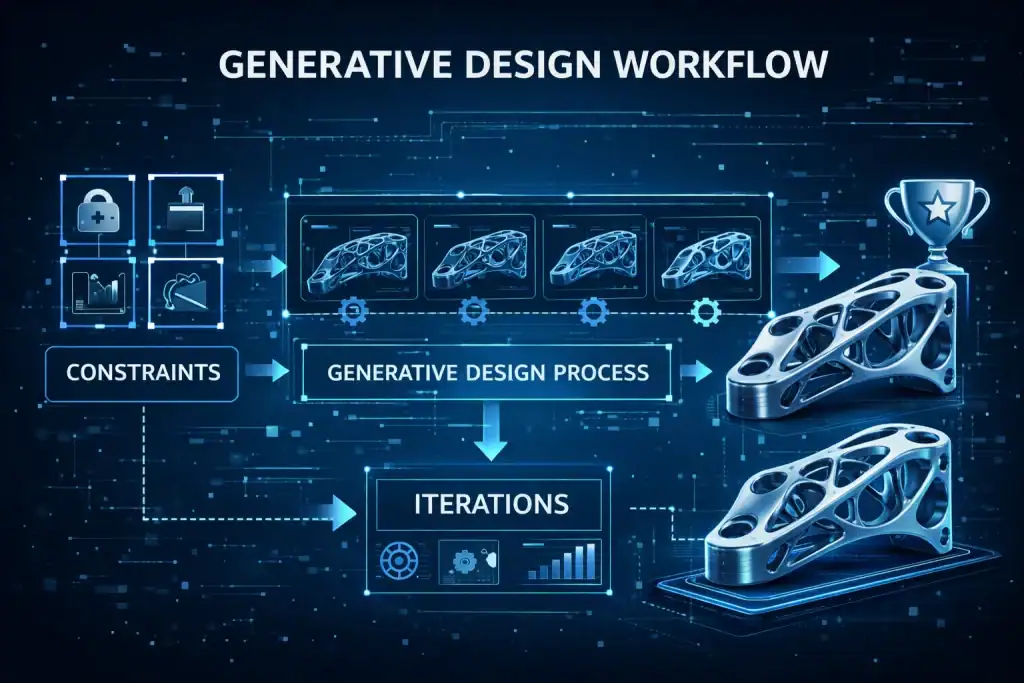

How Does Generative Design Work?

It operates by combining computational algorithms with user-defined constraints. The process typically follows these steps:

- Defining Objectives: Designers set goals, such as minimizing cost, reducing weight, or improving durability.

- Inputting Constraints: Materials, environmental factors, and manufacturing methods are added.

- Running Simulations: AI algorithms explore vast possibilities, simulating real-world performance.

- Evaluating Outcomes: The system ranks designs based on how well they meet objectives.

- Refinement and Selection: Designers refine the best options for practical implementation.

Consider how Autodesk’s Fusion 360 software enables product designers to explore hundreds of design possibilities in minutes, streamlining the prototyping process.

Pros and Cons

Generative design is a game-changer, but like any innovation, it has advantages and drawbacks.

| Advantages | Challenges |

|---|---|

| Efficiency: Reduces time spent on manual iteration. | Complexity: Requires specialized knowledge to operate. |

| Sustainability: Minimizes material waste. | High Costs: Software and computational resources are expensive. |

| Innovation: Promotes creativity and unique designs. | Dependence on AI: May limit human oversight. |

| Customization: Tailors solutions to specific needs. | Implementation Barriers: Integration can be challenging. |

Key Companies in Generative Design

Several companies are driving the adoption and innovation of it.

Notable Leaders

- Autodesk: Known for Fusion 360 and generative design capabilities in manufacturing.

- Siemens: Offers NX software with advanced optimization features.

- Dassault Systèmes: Provides SOLIDWORKS for topology optimization and more.

- nTopology: Specializes in complex lattice structures for engineering.

- Bentley Systems: Focuses on it for infrastructure and urban planning.

These companies are reshaping industries, enabling designers to achieve unprecedented results.

Applications

Generative design’s versatility has made it indispensable in various sectors. Its applications include:

Manufacturing and Product Design

- Lightweight Components: Automotive and aerospace companies, like Airbus, use it to create lighter parts.

- Optimized Prototypes: Speeds up prototyping and reduces costs.

Architecture and Construction

- Sustainable Buildings: Designers create energy-efficient structures.

- Complex Facades: Generative algorithms design intricate, unique exteriors.

Healthcare and Biomedicine

- Custom Prosthetics: Tailors prosthetics to individual needs.

- Bioprinting: Assists in creating bio-compatible implants.

Fashion and Textiles

- Innovative Patterns: Generates unique, adaptive fabric designs.

- Sustainability Efforts: Optimizes material usage for eco-friendly fashion.

Whether in urban planning or cutting-edge product innovation, generative design continues to push boundaries.

Conclusion

Generative design is not just a buzzword; it represents a paradigm shift in how we approach creativity, efficiency, and innovation. From transforming product design to shaping the cities of tomorrow, its potential is vast and still unfolding. Embracing this technology is essential for industries aiming to stay competitive in an increasingly data-driven world.